credit – MIT Sustainable Concrete Lab

credit – MIT Sustainable Concrete LabScientists from MIT have created a conductive “nanonetwork” inside a unique concrete mixture that could enable everyday structures like walls, sidewalks, and bridges to store and release electrical energy.

It’s perhaps the most ubiquitous man-made material on Earth by weight, but every square foot of it could, with the addition of some extra materials, power the world that it has grown to cover.

Known as e c-cubed (ec3) the electron-conductive carbon concrete is made by adding an ultra-fine paracrystalline form of carbon known as carbon black, with electrolytes and carbon nanoscales.

Not a new technology, MIT reported in 2023 that 45 cubic meters of ec3, roughly the amount of concrete used in a typical basement, could power the whole home, but advancements in materials sciences and manufacturing processes has improved the efficiency by orders of magnitude.

Now, just 5 cubic meters can do the job thanks to an improved electrolyte.

“A key to the sustainability of concrete is the development of ‘multifunctional concrete,’ which integrates functionalities like this energy storage, self-healing, and carbon sequestration,” said Admir Masic, lead author of the new study and associate professor of civil and environmental engineering at MIT.

“Concrete is already the world’s most-used construction material, so why not take advantage of that scale to create other benefits?”

The improved energy density was made possible by a deeper understanding of how the nanocarbon black network inside ec3 functions and interacts with electrolytes. Using focused ion beams for the sequential removal of thin layers of the ec3 material, followed by high-resolution imaging of each slice with a scanning electron microscope.

The team across the EC³ Hub and MIT Concrete Sustainability Hub was able to reconstruct the conductive nanonetwork at the highest resolution yet. This approach allowed the team to discover that the network is essentially a fractal-like “web” that surrounds ec3 pores, which is what allows the electrolyte to infiltrate and for current to flow through the system.

“Understanding how these materials ‘assemble’ themselves at the nanoscale is key to achieving these new functionalities,” adds Masic.

Equipped with their new understanding of the nanonetwork, the team experimented with different electrolytes and their concentrations to see how they impacted energy storage density. As Damian Stefaniuk, first author and EC³ Hub research scientist, highlights, “we found that there is a wide range of electrolytes that could be viable candidates for ec3. This even includes seawater, which could make this a good material for use in coastal and marine applications, perhaps as support structures for offshore wind farms.”

At the same time, the team streamlined the way they added electrolytes to the mix. Rather than curing ec3 electrodes and then soaking them in electrolyte, they added the electrolyte directly into the mixing water. Since electrolyte penetration was no longer a limitation, the team could cast thicker electrodes that stored more energy.

The team achieved the greatest performance when they switched to organic electrolytes, especially those that combined quaternary ammonium salts — found in everyday products like disinfectants — with acetonitrile, a clear, conductive liquid often used in industry. A cubic meter of this version of ec3—about the size of a refrigerator—can store over 2 kilowatt-hours of energy. That’s about enough to power an actual refrigerator for a day.

While batteries maintain a higher energy density, ec3 can in principle be incorporated directly into a wide range of architectural elements—from slabs and walls to domes and vaults—and last as long as the structure itself.

“The Ancient Romans made great advances in concrete construction. Massive structures like the Pantheon stand to this day without reinforcement. If we keep up their spirit of combining material science with architectural vision, we could be at the brink of a new architectural revolution with multifunctional concretes like ec3,” proposes Masic.

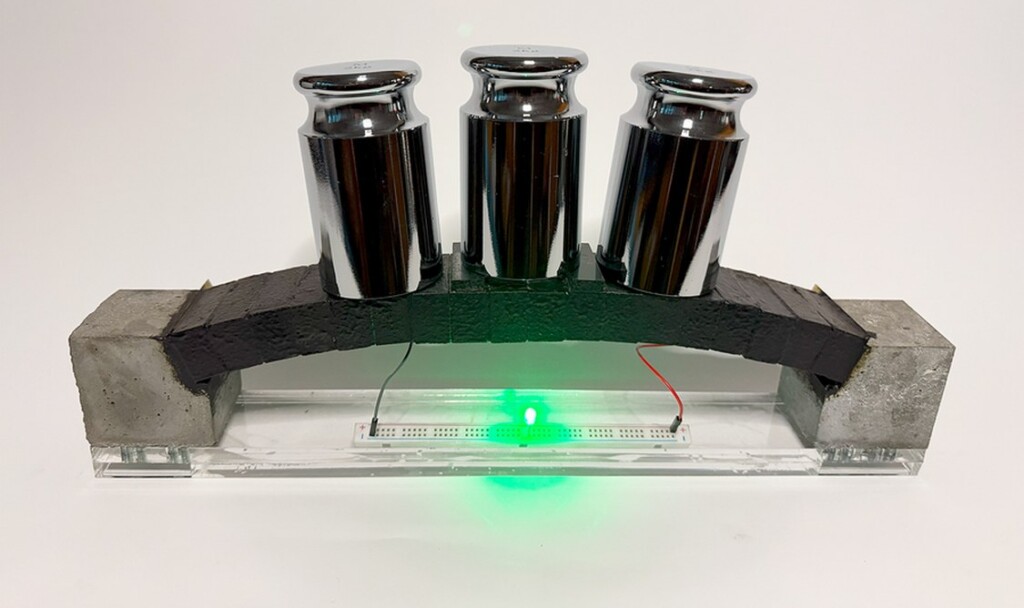

Taking inspiration from Roman architecture, the team built a miniature ec3 arch to show how structural form and energy storage can work together. Operating at 9 volts, the arch supported its own weight and additional load while powering an LED light.

The latest developments in ec³ technology bring it a step closer to real-world scalability. It’s already been used to heat sidewalk slabs in Sapporo, Japan, due to its thermally conductive properties, representing a potential alternative to salting.

“What excites us most is that we’ve taken a material as ancient as concrete and shown that it can do something entirely new,” says James Weaver, a co-author on the paper who is an associate professor of design technology and materials science and engineering at Cornell University, as well as a former EC³ Hub researcher. “By combining modern nanoscience with an ancient building block of civilization, we’re opening a door to infrastructure that doesn’t just support our lives, it powers them.” Cement Supercapacitors Could Turn the Concrete Around Us into Massive Energy Storage Systems

Iron-air batteries for stable power – Credit: Form Energy

Iron-air batteries for stable power – Credit: Form Energy

Altaeros’ BAT – credit, Altaeros, via MIT

Altaeros’ BAT – credit, Altaeros, via MIT_89230.jpg) (Image: First Light Fusion)

(Image: First Light Fusion)